Products

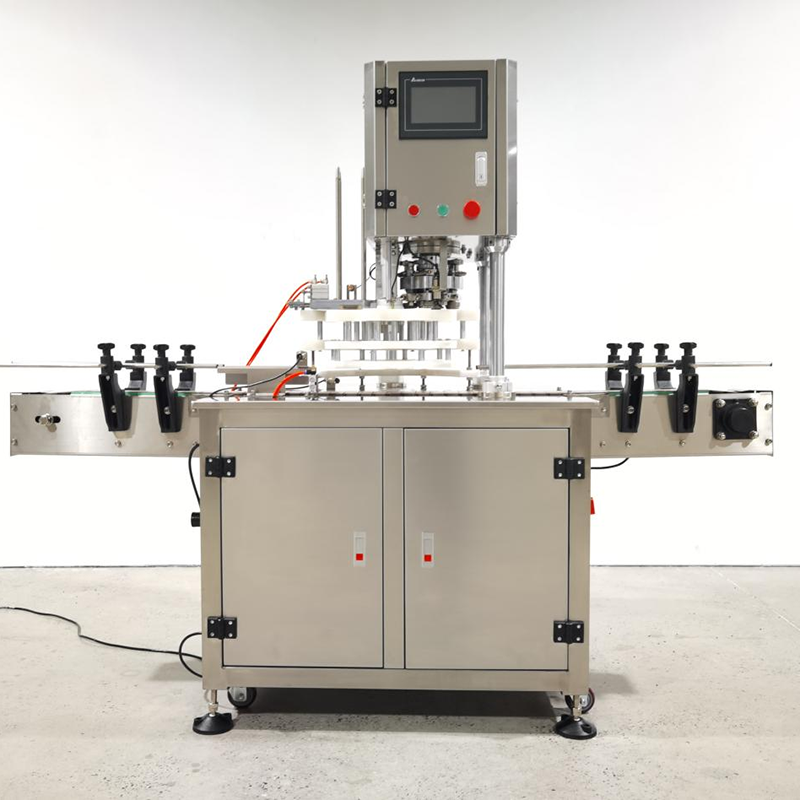

Full Automatic Can Sealing Machine DC-130

Characteristic Description:

1. Joint control device of tank cover: when there is a tank body entering, the tank cover is allocated accordingly. If there is no tank, there is no cover;

2. Touch screen interface, PLC program control, fully intelligent, simple and easy to operate

3. With high production capacity and high degree of automation, it is suitable to be used as the equipment of can sealing production line;

4. The appearance is made of stainless steel, and the sealing roller is made of chromium steel, which has high hardness, good wear resistance, no rust, and excellent sealing performance.

Performance description:

1. Unmanned operation, fully automatic capping and sealing, according to the rising trend of labor price level, the equipment will become the mainstream model;

2. During the sealing process, the tank body is designed not to rotate, which has good protection for the product and the tank body, high processing accuracy, and the sealing quality is better than that of domestic similar products;

3. The production efficiency of the machine is 2~3 times that of the semi-automatic sealing machine, and due to the full-automatic lower cap and can sealing device, the labor cost is saved and the production efficiency is improved at the same time;

4. It is suitable for sealing all kinds of round cans, such as tinplate cans, aluminum alloy cans, paper cans and so on. It is easy to operate and learn. It is an ideal equipment for food, beverage, pharmaceutical and other industrie

Machine material: stainless steel can sealing knife wheel: the four knife wheels (two first can sealing rollers and two second can sealing rollers) have better sealing performance than the ordinary two knife wheels

Number of cans: 1

Can sealing speed: 35 cans / min (depending on the bottle type)

Can sealing height: 30-250 (if it exceeds 50mm, the support rod needs to be replaced or the rotary table needs to be superimposed)

Applicable bottle diameter range: 50-130mm (mold customized according to caliber)

Configuration table:

|

Serial number |

Part name |

Manufacturer |

|

1 |

Touch screen |

Delta |

|

2 |

Detecting electric eye |

Otonix |

|

3 |

Servo motor |

Delta |

|

5 |

Adjustable speed motor |

Zhejiang Meili |

|

6 |

Cylinder |

AirTAC |

|

7 |

Solenoid valve |

AirTAC |

|

8 |

Air switch |

chint |