Products

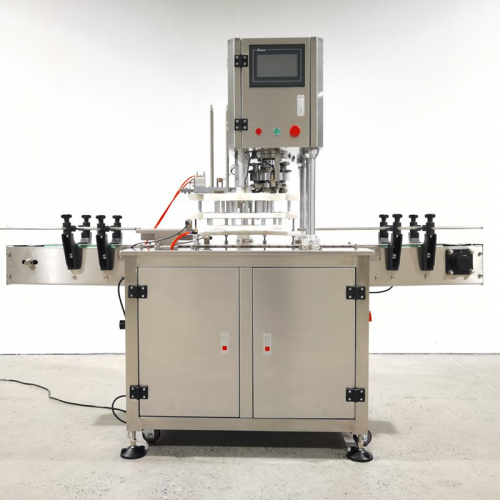

Vacuum Can Sealing Machine

The automatic vacuum capping machine simulates the manual capping action, and the capping process has no damage to the bottle cap. It is compatible with a variety of bottle types. When changing bottle types, you can adjust the equipment and replace accessories, which is simple and convenient. The qualified rate of normal screw cap is high. The capping speed is fast and the cost is low. The operation of the whole machine is humanized without professional technology. It is an ideal choice for enterprise automatic production.

Capping machine workflow:

Put the cap — screw the cap — output of finished products

1. Power supply voltage (v/hz):ac 220/50

2. Bottle sealing height (mm):80-150

3. Applicable cover diameter (mm): 50-70

4. Applicable bottle diameter (mm): 50-80

5. Working pressure (MPA):0.5-0.8

6. Weight: 350kg

7. Output (bottle / hour):25-35 bottles /min

8. Overall dimension: (L × W × H)(mm): 800*900*1900mm

9. Height of conveying line: 800 ± 50mm (it can be determined according to the original production line of the customer)

Main configuration list of electrical components of automatic single head capping machine:

|

Serial number |

Name |

Model or quantity |

brand/Origin |

|

1 |

Counting photoelectricity |

KR-Q50N-V42 |

Panasonic, Japan |

|

2 |

Proximity switch |

XS612B4NBL2 |

Sk,Germany |

|

3 |

Switching Mode Power Supply |

ABL2REM24065 |

Schneider, France |

|

4 |

Small relay |

Schneider, France |