Products

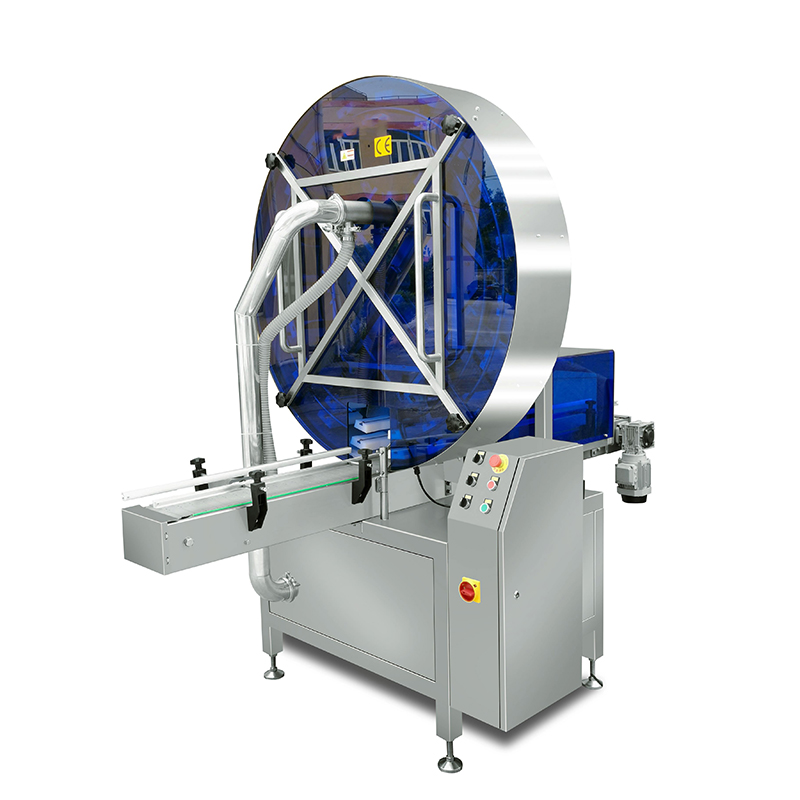

Short Lead Time for How much is the filling line - Robot Bottle Unscrambler -zun shang

Short Lead Time for How much is the filling line - Robot Bottle Unscrambler -zun shang Detail:

Equipment storage hoist:

Introduce the disordered bottles into the lifting storage hopper. The hopper will automatically feed according to the number of bottles in the lifting mechanism of the front section, and the front section will automatically stop when full.

Belt conveyor arrangement mechanism:

The elevator lifts the bottles into the belt arrangement mechanism, arranges the heads and tails of the bottles in different directions, and waits for them to enter the manipulator gripping mechanism. The width of the entire belt arrangement mechanism is adjustable to adapt to the bottle types with different diameters.

Mechanical gripper mechanism:

The mechanical gripper mechanism is composed of a servo linkage mechanism, which cooperates with photoelectric detection to detect the orientation of the bottle mouth. In the process of grasping, the direction of the bottle is reversed to ensure that the bottle delivered by the customer on site is placed with the bottle mouth upward.

Electric control panel:

PLC servo or step control system is adopted to ensure the accuracy and stability of the equipment.

Features:

1: PLC, touch screen control, convenient for customers to change the bottle type, and visual operation on the touch screen.

2: Wide compatibility range, suitable for a variety of bottle types, no need to change the mold.

3: Automatic stop of full bottle conveying, automatic start of bottle shortage, perfect replacement of manual operation

Working principle of the equipment: empty bottles to be sorted are poured into the elevator. After passing through the lifting structure, the bottles are placed flat on the belt conveyor mechanism. After passing through the belt conveyor, the bottles are sent to the automatic detection mechanism. The automatic detection mechanism is used to distinguish the positive and negative sides of the bottles, and then send signals to the system to control the robot arm to turn over and transfer. Finally, the bottles are in the state with the bottle mouth upward after entering the next process, The average capacity of the equipment is expected to be 30-70 bottles per minute, and the structure is stable and reliable.

|

Model |

LC-JSS-04 |

|

Host size |

Length 2.5m, width 1.3m, height 1m (size can be customized) |

|

Production speed |

1800 bottles / hour (according to bottle type) |

|

Air supply pressure |

0.3-0.4 MPa |

|

Gas consumption |

0.1 m3 / min |

|

Suitable for bottle type |

Bottle type provided by the customer |

|

Host power |

1.1KW 220V voltage |

|

Equipment weight |

0.35T |

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs of Short Lead Time for How much is the filling line - Robot Bottle Unscrambler -zun shang , The product will supply to all over the world, such as: Oman , Maldives , Slovakia , Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, be sure to click the button to acquire additional nformation.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.