Products

Personlized Products Hot dog Filling production line - Horizontal Bottle Unscrambler -zun shang

Personlized Products Hot dog Filling production line - Horizontal Bottle Unscrambler -zun shang Detail:

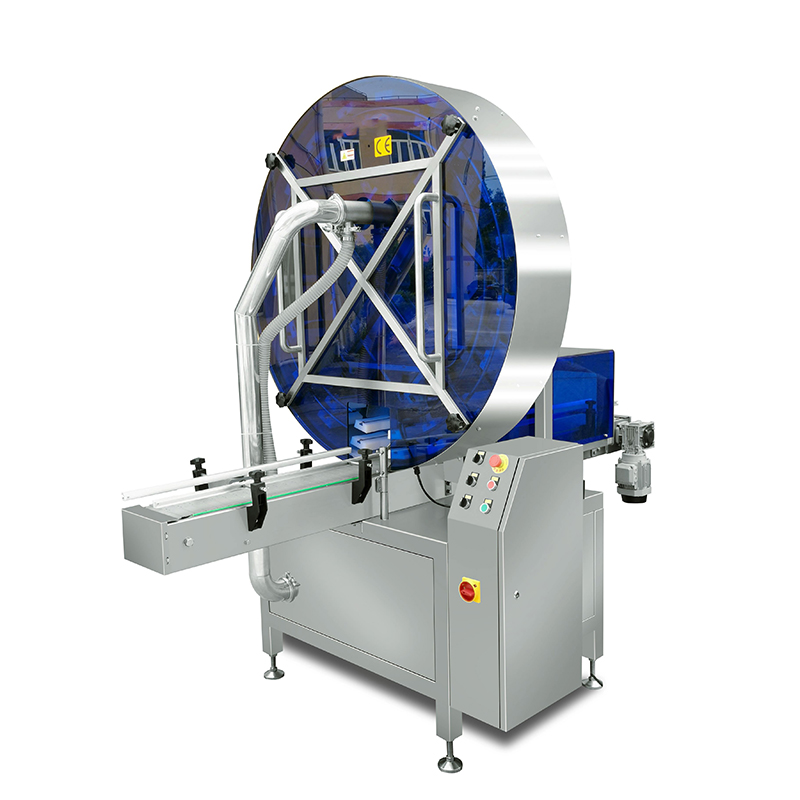

The equipment is designed with the elevator and the main machine as a whole to save space. It is mainly used for finishing wide mouth bottles with large capacity difference. The width of some mechanisms can be adjusted to adapt to a wide range of bottle types.

Claw high-speed centrifugal disk, intelligent touch operating system:

The equipment adopts high-speed centrifugation to centrifuge the bottle to the edge of the equipment for high-speed output.

Touch screen control system, easy to change equipment parameters.

The electrical part of PLC adopts international brands, with reliable control and high degree of automation.

Double bottle splitting belt, increasing bottle dispensing efficiency and even bottle splitting!

The optical fiber sensor detects the bottle hooking mechanism to ensure the stable operation of the bottle hooking, and has the function of fault alarm and shutdown!

The outlet of the equipment adopts multi-level belt output. Firstly, the bottle body is stabilized. Through clamping and conveying, the hook and claw bottle turning mechanism are connected to realize high-speed turning. The width of the belt is adjustable and the range of application is wide.

1. Applicable range and bottle size:

the full-automatic bottle trimming machine is a patented product developed by the company. This product is widely used for multifunctional full-automatic bottle trimming of products in the food, beverage industry, pharmaceutical industry, condiment, juice, milk and other industries.

Bottle type customization machine provided by customers

Note: the above models are standard models, and special bottle types shall be negotiated in advance

2. Equipment advantages:

Advanced function, simple operation, compact structure, the whole machine adopts mature PLC control system to make the whole machine run stably and at high speed

The operating system adopts button control, which is simple, practical and efficient

The body is made of stainless steel to ensure that the bottle is clean and pollution-free

Imported low-voltage electrical components with stable performance and extremely low failure rate.

When connected, it has the bottle blocking alarm function of air conveying, and automatically starts after processing

Compared with the traditional bottle sorting machine, it is small in size and fast in speed

・ wide range of use, multi-purpose and strong adaptability!

the number of hoists changes the corresponding position according to the site, which greatly adapts to the production site

It is convenient to connect and connect. After the bottle is out, it can be directly connected by air or transported.

3. Brief description of bottle sorting machine:

This machine is used for sorting out disordered polyester bottles. The disordered bottles are sent to the bottle storage ring of the bottle sorting machine through the elevator. By the centrifugal force of the rotary table, the bottle ends are connected to the centrifugal disk, and the outlet multi-level belt mechanism. By stabilizing the bottle body, the bottle is clamped into the claw mechanism, the bottle mouth is lifted and turned forward, and the bottle bottom cannot be hooked forward. Finally, the bottle mouth runs forward and backward, and then the bottle is upright through the last level belt, The bottle finishing process is completed, and it is output to the next process through the pneumatic bottle conveying system. The machine body is made of high-quality stainless steel, and other parts are made of non-toxic and durable series materials. Some imported parts are selected for the electrical and pneumatic systems, and the whole working process is controlled by PLC programming. Therefore, the equipment has low failure rate and high reliability.

4. Working process:

First, manually pour the bottle into the elevator bucket;

The bottle is sent to the sorting bin of the bottle sorting machine by the elevator;

The bottles are put into the bin of the bottle sorting machine for sorting, high-speed centrifugal output, multi-stage belt output, claw turning the bottle, and belt clamping to keep the bottle upright

Product detail pictures:

Related Product Guide:

We normally believe that one's character decides products' quality, the details decides products' high-quality ,while using the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Personlized Products Hot dog Filling production line - Horizontal Bottle Unscrambler -zun shang , The product will supply to all over the world, such as: Kenya , Sri Lanka , azerbaijan , Our solutions have national accreditation requirements for qualified, good quality products, affordable value, was welcomed by individuals all over the world. Our products will continue to improve inside the order and appear forward to cooperation with you, Definitely should any of those goods be of curiosity to you, be sure to letus know. We'll be satisfied to supply you a quotation up on receipt of the detailed needs.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.