Products

OEM Manufacturer Hot dog Packaging production line - New Type High-speed Bottle Unscrambler -zun shang

OEM Manufacturer Hot dog Packaging production line - New Type High-speed Bottle Unscrambler -zun shang Detail:

The original spring and electromagnetic clutch cooperate to make the operation more stable, and automatically disconnect the power in case of fault alarm, effectively protecting human and machine safety

The linear sliding parts are made of German Eagles wear-resistant sleeve, which is maintenance free for life. All aluminum parts are made of 7075a imported aviation aluminum materials, processed by the machining center, and the sliding rod is high-precision ground

The equipment adapts to the one button automatic adjustment of bottle type change. The operation interface is simple and reliable. When changing the bottle type, only the bottle height and the compensation amount are input. The customer can also record the bottle capacity. Click the bottle type switch, and the internal servo motor of the equipment automatically calculates the bottle type to be produced according to the data, and automatically adjusts it in place. The data has power-off holding, and the one-time input is permanently saved to save the adjustment time

1. Applicable range:

1.1: the full-automatic bottle trimming machine is a patented product developed by the company. This product is widely used for multifunctional full-automatic bottle trimming of products in the food, beverage industry, pharmaceutical industry, condiment, juice, milk and other industries.

Bottle adaptation range: (other ranges can be customized)

Diameter: 55mm-70mm

Height: 130mm-230ml

Capacity: 280ml-600ml

2. Equipment advantages:

・ no compressed air, the first in the industry, energy saving and emission reduction, reducing secondary pollution of bottles!

Advanced function, simple operation, compact structure, the whole machine adopts mature PLC control system to make the whole machine run stably and at high speed

・ the new type of bottle sorting machine is automatically adjusted by one button, which is convenient and fast, and is the first in the industry with strong compatibility.

The equipment has many patents. It is equipped with a position display according to the bottle type and can be adjusted according to the bottle type. It is unique in China.

The operating system adopts touch screen control, which is simple, practical and efficient

The body is made of stainless steel to ensure that the bottle is clean and pollution-free

Imported low-voltage electrical components with stable performance and extremely low failure rate.

It has functions such as bottle jam shutdown and alarm when the equipment is abnormal

When connected, it has the function of air blowing or conveying bottle blocking alarm, and automatically starts after processing

Compared with the traditional bottle sorting machine, it is small in size and fast in speed

・ wide range of use, multi-purpose and strong adaptability!

the number of hoists changes the corresponding position according to the site, which greatly adapts to the production site

It is convenient to connect and connect. After the bottle is out, it can be directly connected by air or transported.

|

Equipment configuration sheet |

|||||

|

Serial number |

mechanism |

Specifications |

model |

brand |

|

|

1 |

Main body |

diameter2.0m |

LCSUS304 3.0T |

Zhengzhou Lichuang |

|

|

2 |

Main rotary table motor |

0.2KW /15 |

61K200GU-YFT |

Taiwan Chenggang |

|

|

3 |

Inner rotary table motor |

0.2KW /120 |

61K200GU-YFT |

Taiwan Chenggang |

|

|

4 |

Lifting motor |

0.37KW /30 |

YS-7124 |

Standard configuration |

|

|

5 |

Brush Motor |

40W/5 |

51K40RGN-C |

Taiwan Chenggang |

|

|

6 |

Bearing |

Tapered roller bearing |

Equipment standard configuration |

Harbin |

|

|

7 |

Frequency converter |

0.75KW |

VLTFC51 |

Danfoss |

|

|

8 |

PLC |

Control system |

SMART200 |

Siemens |

|

|

9 |

touch screen |

Embedded integrated touch screen |

SMART |

Siemens | |

|

10 |

electrical |

Schneider Electric |

Equipment high configuration |

Schineider |

|

|

11 |

sensor |

Photoelectric, proximity switch |

Equipment high configuration |

SICK/OMRON |

|

|

12 |

Hopper |

1200L/1300L*2500W*2700H |

Capacity (according to bottle type) |

Zhengzhou Lichuang |

|

|

13 |

Rated total output |

12000BPH |

Stable production capacity |

According to the bottle type | |

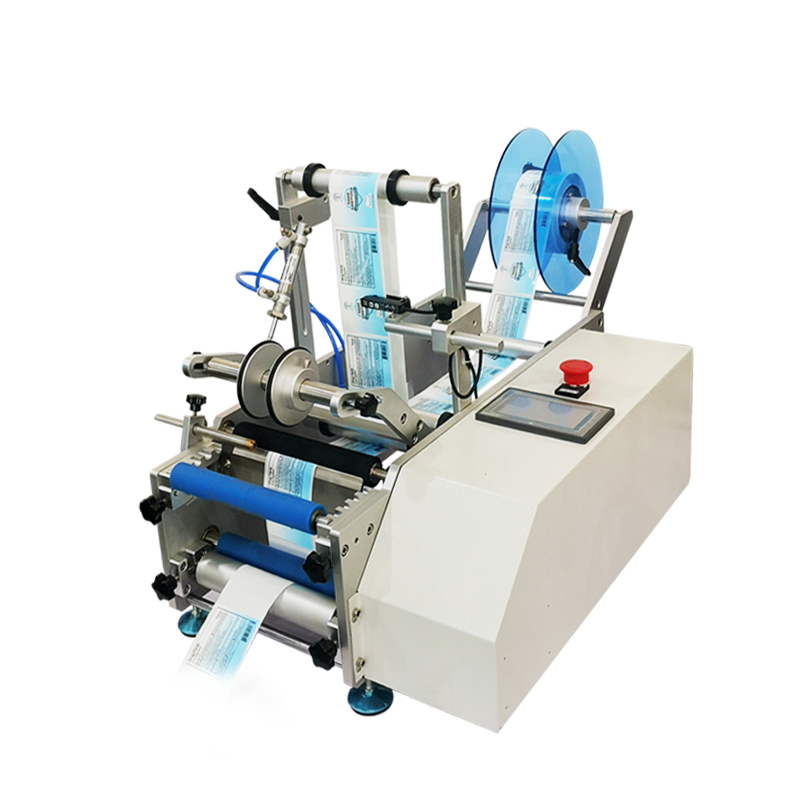

Product detail pictures:

Related Product Guide:

We take pleasure in a really excellent name amongst our shoppers for our exceptional product or service excellent, competitive rate and also the greatest services for OEM Manufacturer Hot dog Packaging production line - New Type High-speed Bottle Unscrambler -zun shang , The product will supply to all over the world, such as: Georgia , United States , Guinea , Our items are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!