Products

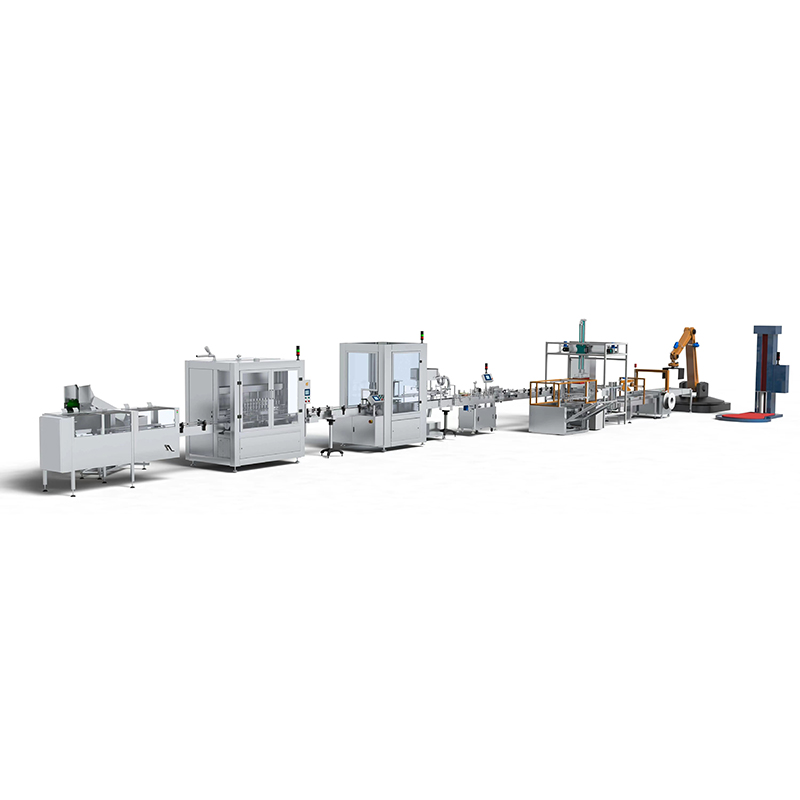

Manufactur standard Lantus Filling line - Rolling Labeling Machine -zun shang

Manufactur standard Lantus Filling line - Rolling Labeling Machine -zun shang Detail:

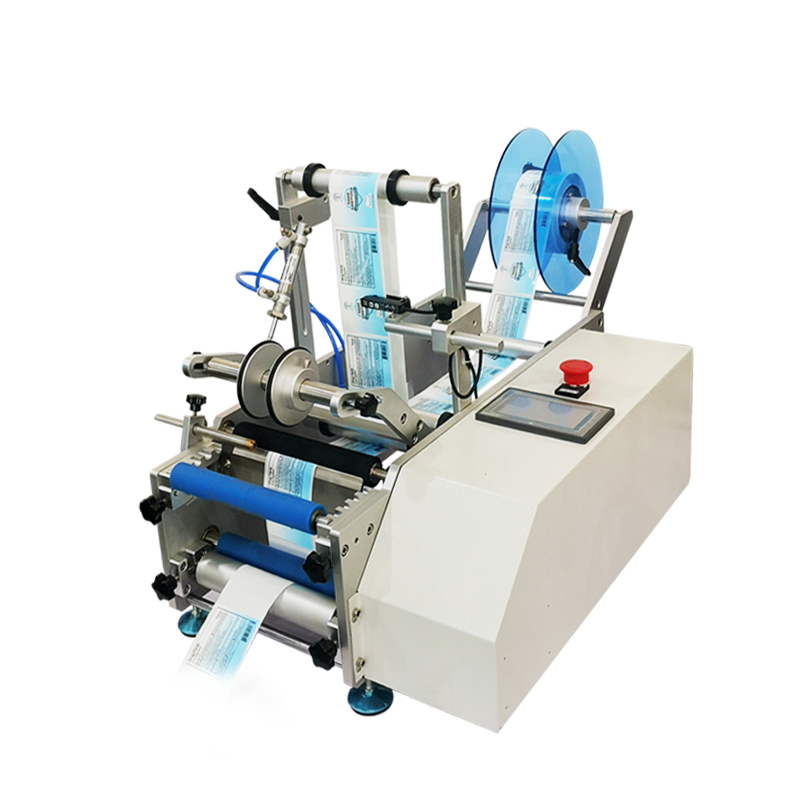

Basic use

It is applicable to the labeling of round bottles in pharmaceutical, food, daily chemical and other industries. It can be labeled in full circle and half circle.

Optional automatic rotary table bottle sorting machine can be directly connected to the front-end production line and automatically send bottles to the labeling machine to increase efficiency.

Optional ribbon coding and labeling machine can be configured to print the production date and batch number online, reduce the bottle packaging process and improve the production efficiency.

Scope of application

Applicable labels: self adhesive label, self adhesive film, electronic supervision code, bar code, etc.

Applicable products: products requiring labels or films on the circumferential surface.

Application Industry: widely used in food, medicine, cosmetics, daily chemicals, electronics, hardware, plastics and other industries.

Application examples: pet round bottle labeling, plastic bottle labeling, food can, etc.

working process

* core working principle: after the product is separated by the bottle separating mechanism, the sensor detects the passing of the product and sends back the signal to the labeling control system. At the appropriate position, the control system controls the motor to send out the label and attach it to the position where the product is to be labeled. The product flows through the labeling device, the labeling belt drives the product to rotate, the label is rolled, and the labeling of one label is completed

* operation process: release the product (can be connected to the assembly line) – > product delivery (automatic realization of the equipment) – > Product Separation – > Product Detection – > labeling – > re labeling – > collect the labeled products.

Technical parameters: the following are the technical parameters of the standard model. Other special requirements and functions can be customized

◆ applicable label length (mm): 20mm ~ 314mm

◆ applicable label width (bottom paper width / mm): 15mm ~ 150mm

◆ applicable product diameter (for round bottles) and height: diameter: φ 25mm~ φ 100mm

Height: 25mm ~ 230mm

◆ applicable standard coil outer diameter (mm): φ 300mm

◆ applicable inner diameter of standard roll (mm): φ 76mm

◆ labeling accuracy (mm): ± 1mm

◆ standard output speed (M / min): servo: 5 ~ 25m / min

Step: 5 ~ 19m / min

◆ labeling speed (PCS / min): step: 30 ~ 120pcs / min (related to bottle and label size)

Servo: 40 ~ 180pcs / min

◆ conveying speed (M / min): 5 ~ 25m / min

◆ weight (kg): about 185kg

◆ frequency (Hz): 50Hz

◆ voltage (V): 220V

◆ power (W): 530W (traction stepping)

980W (traction servo)

◆ overall dimension of equipment (mm) (length × wide × Height): 1950mm × 1100mm × 1300mm

Functional features

Wide range of application, can meet the full circle labeling or semi circle labeling of round bottles, simple labeling switching between bottles and convenient adjustment;

The label overlap is high. The deviation correcting mechanism is adopted for the label belt. The label belt does not deviate. The three directions of X / Y / Z and the inclination of the labeling position can be adjusted in eight degrees of freedom, and there is no dead angle. The label overlap is high;

The labeling quality is excellent, and the elastic pressure label covering belt is used. The labeling is flat and free of wrinkles, so as to improve the packaging quality;

Flexible application, vertical labeling of bottles, with automatic bottle splitting function, can be produced in a single machine or connected to an assembly line;

intelligent control, automatic photoelectric tracking, with no labeling, no labeling automatic correction and label automatic detection functions to prevent missing labeling and label waste;

High stability, advanced electronic control system composed of Panasonic PLC + vinylon touch screen + Panasonic needle eye + German Sike label eye, supporting equipment 7 × 24-hour operation;

The adjustment is simple, and the labeling speed, conveying speed and bottle splitting speed can be adjusted steplessly according to needs;

Solid and durable, adopting three-bar adjustment mechanism, making full use of the stability of the triangle, the whole machine is solid and durable. Made of stainless steel and high-grade aluminum alloy, meeting GMP production requirements;

Optional functions:

① Hot coding / online coding / ink-jet coding function;

② Automatic feeding function (considering the product);

③ Automatic material receiving function (considering the product);

④ Add labeling device;

⑤ Circumferential positioning and labeling function;

⑥ Other functions (customized according to customer requirements).

Product detail pictures:

Related Product Guide:

We've one of the most innovative manufacturing devices, experienced and qualified engineers and workers, recognized good quality handle systems and also a friendly experienced income team pre/after-sales support for Manufactur standard Lantus Filling line - Rolling Labeling Machine -zun shang , The product will supply to all over the world, such as: Macedonia , Accra , Georgia , We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Allow us to work together to write a brilliant new chapter!

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!