Products

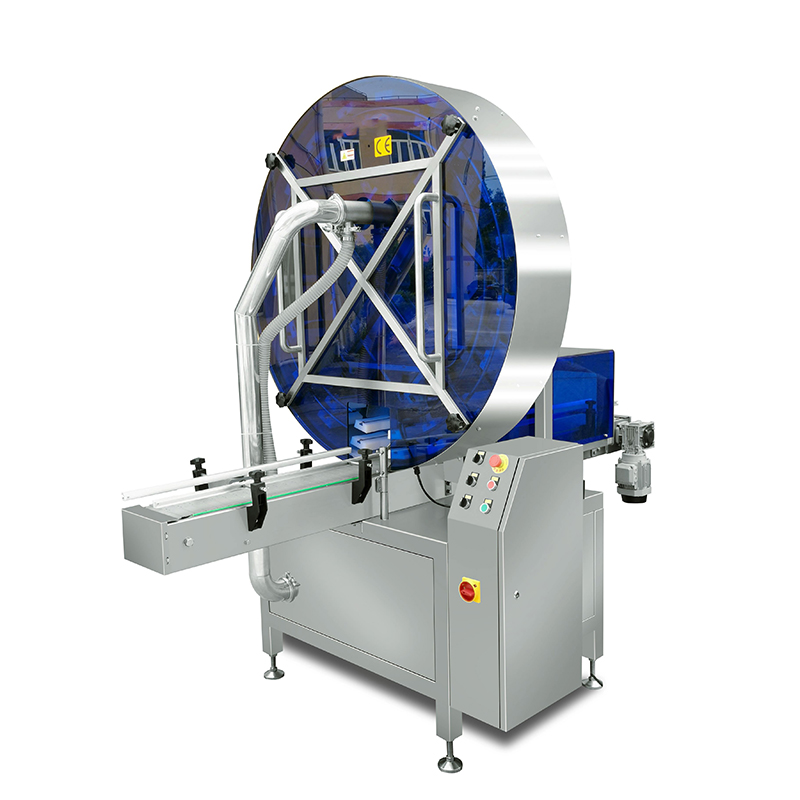

Hot Selling for Massive Gainer Packaging equipment - Round Bottle Labeling Machine -zun shang

Hot Selling for Massive Gainer Packaging equipment - Round Bottle Labeling Machine -zun shang Detail:

1. Basic purpose

It is applicable to labeling on the circumferential surface of round bottles. Single label and double label can be attached. The distance between the front and back double labels can be flexibly adjusted, such as labeling of gel water round bottles and food round cans. It is widely used in cosmetics, food, medicine, disinfection water and other industries. Optional circumferential positioning detection device can realize labeling at the specified position on the circumferential surface.

Optional color matching tape coding machine and ink-jet coding machine can print the production date and batch number information on the label and realize the integration of labeling and coding.

2. Scope of application

Applicable labels: adhesive label, adhesive film, electronic supervision code, bar code, etc.

Applicable products: round bottles with a diameter of 30mm ~ 90mm.

Application Industry: widely used in medicine, food, toys, daily chemicals and other industries.

Application examples: disinfection water bottle labeling, gel water double label labeling, red wine bottle positive label positioning labeling, etc.

3. Working process

* core working principle: put the products on the conveyor belt and enter the bottle splitting mechanism. After the bottle splitting mechanism separates the products, the sensor detects the passing of the products and sends back the signal to the labeling control system. At the appropriate position, the control system controls the corresponding motor to send out the labels and attach them to the positions of the products to be labeled. At the same time, the labeling is repeated, and the labeling of one label is completed.

* operation process: place the product conveyor belt (which can be connected to the assembly line) – > product conveying – > Product Separation – > Product Detection – > product positioning – > labeling and re labeling – > collect the labeled products.

Technical parameters: the following are the technical parameters of the standard model. Other special requirements and functions can be customized

◆ applicable label length (mm): 20mm ~ 285mm

◆ applicable label width (bottom paper width / mm): 20mm ~ 160mm

◆ applicable product diameter (for round bottles) and height: diameter: φ 25mm~ φ 90mm

Height: 25mm ~ 300mm

◆ applicable standard coil outer diameter (mm): φ 280mm

◆ applicable inner diameter of standard roll (mm): φ 76mm

◆ labeling accuracy (mm): ± 1mm

◆ standard output speed (M / min): servo: 5 ~ 25m / min

Step: 5 ~ 19m / min

◆ labeling speed (PCS / min): step: 25 ~ 55pcs / min

Servo: 30 ~ 65pcs / min

◆ conveying speed (M / min): 5 ~ 18m / min

◆ weight (kg): about 185kg

◆ frequency (Hz): 50Hz

◆ voltage (V): 220V

◆ power (W): traction step: 570W

Traction servo: 980W

◆ overall dimension of equipment (mm) (length × wide × Height): 1950mm × 1200mm × 1530mm

◆ air pressure (MPA): 0.4 ~ 0.6MPa

Functional features

Powerful function, the same equipment can realize single label labeling and double label labeling of round bottle objects, and the double label spacing can be flexibly adjusted. Optional circumferential positioning detection device can realize the function of positioning and labeling on the circumferential surface;

The label overlap is high, the top pressing mechanism is configured, and the 3-axis positioning mechanism is combined to prevent the bottle from fluctuating up and down and improve the labeling accuracy;

Automatic bottle splitting, adopting elastic type bottle splitting mechanism, effectively eliminating bottle splitting caused by bottle error, and improving stability;

Touch screen control, human-computer interaction interface with operation teaching function, parameter modification is intuitive and clear, and various functions are switched easily;

Intelligent control, automatic photoelectric tracking, with no label, no label automatic correction and label automatic detection functions, to avoid wasting labels and missing labels;

High stability, advanced electronic control system composed of Panasonic PLC + vinylon touch screen + Panasonic needle eye + German Sike label eye, supporting equipment 7 × 24-hour operation;

Solid and sanitary, mainly made of stainless steel and high-grade aluminum alloy, with solid quality and meeting GMP production requirements;

It has automatic shutdown function, production counting function, power saving function (when there is no production within the set time, the equipment will automatically switch to the power saving standby state), production number setting prompt function, parameter setting protection function (parameter setting sub authority management) to facilitate production management;

Optional functions:

① Hot code printing / printing function;

② Automatic feeding function (vertical bottle feeder);

③ Automatic material receiving function (considering the product);

④ Add labeling device;

⑤ Non standard bottle removal function (customized according to customer requirements).

Product detail pictures:

Related Product Guide:

We generally believe that one's character decides products' top quality, the details decides products' high-quality ,along with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Hot Selling for Massive Gainer Packaging equipment - Round Bottle Labeling Machine -zun shang , The product will supply to all over the world, such as: Vancouver , Miami , Algeria , We are fully aware of our customer's needs. We provide high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!