Products

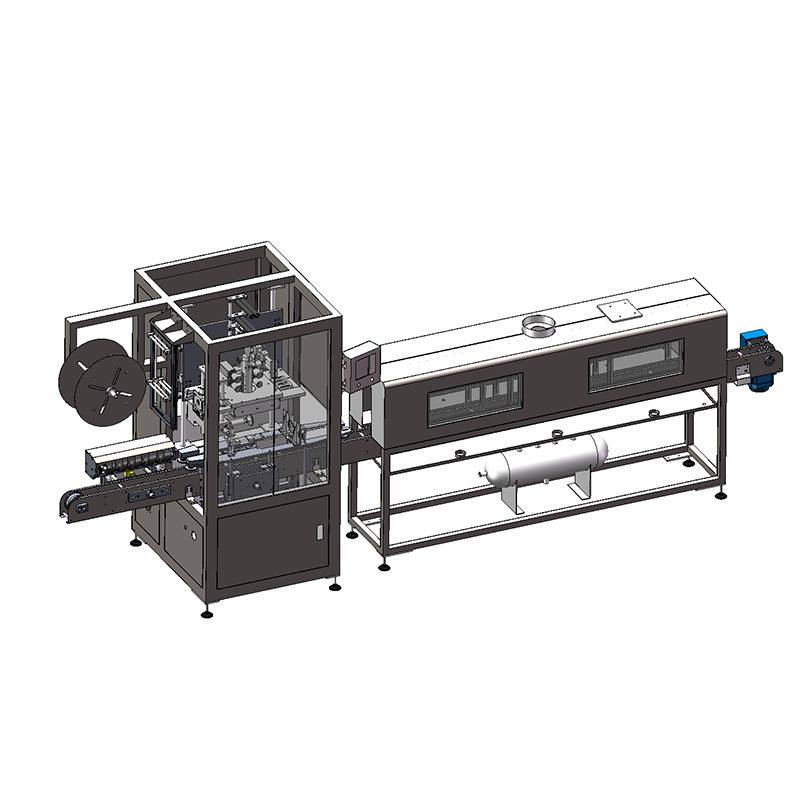

Good quality aluminium Filling line - Bottle Blowing Machine -zun shang

Good quality aluminium Filling line - Bottle Blowing Machine -zun shang Detail:

Z-sun ty8800 high-speed one out six full-automatic bottle blowing machine, through continuous technical updates and design improvements, fully servo electric drive, is currently stable at 2000 bottles / hour -10000 bottles / hour, especially suitable for the production of water, beverages, condiments, food packaging and other bottles and cans, with high speed, continuous 24-hour stable work, and an original thermostatic control system, which reduces energy consumption by more than 25%.

At present, there are one out of two, one out of four, one out of six specifications, which are characterized by:

1. Taiwan Delta PLC microcomputer controller is adopted, with man-machine interface and simple operation

2. The patented automatic feeding device can transfer the blank bottle from the feeding trough to the multi position mechanical arm, with high transmission efficiency and stable work. The intelligent early warning feeding system will automatically alarm when there is no bottle blank in the feeding silo to remind workers to feed, save time and improve production efficiency.

3. Patented automatic bottle blowing machine transmission system, unique bottle blank base design, fast transmission speed, low energy consumption

4. The original constant temperature control infrared heating system, with the temperature of each infrared lamp controlled independently, ensures that the bottle blank is heated evenly, and improves the success rate of bottle blowing.

5. Full servo electric drive, high bottle blowing efficiency, stable operation, relative to hydraulic drive, no pollution, low noise

6. The key pneumatic components are imported from abroad, with stable and accurate operation and long service life

7. The double arm connecting rod mold locking structure design, which has been optimized and improved for many times, is more reasonable in structural design and has strong mold locking force. It is equipped with aviation aluminum bottle blowing machine mold, which is light in weight, convenient and fast to replace mold, and less energy consumption

8. Air bag supercharging plate is adopted to effectively solve the problem of bulky mold expansion and mold closing line

9. The whole machine adopts super standard anti-seismic structure design, with strong anti-seismic capacity and strong equipment stability

10. The intelligent fault early warning system can automatically alarm in case of equipment failure, and can quickly locate the fault location and maintain it quickly

11. Equipped with gas source recovery system, it can recover and save more than 25% of high-pressure gas.

Technical parameters of one out six bottle blowing machine

|

Project |

Unit |

TY-HS8800 |

|

|

Molding group specification |

Bottle spacing |

mm |

76 |

|

Number of cavities |

cav |

6 |

|

|

Bottle type specification |

Maximum bottle capacit |

L |

0.6 |

|

Tooth size |

mm |

18-38 |

|

|

Maximum bottle diameter |

mm |

68 |

|

|

Maximum bottle height |

mm |

240 |

|

| Theoretical capacity |

hph |

9000 |

|

|

Host power Specifications |

Maximum heating power |

kw |

72 |

|

heating power |

kw |

30 |

|

|

High pressure air compressor |

Bottle blowing pressure |

mpa |

30 |

|

High pressure gas consumption |

m3/min |

5 |

|

|

Low pressure air compressor |

pressure |

map |

5 |

|

Low pressure gas consumption |

m3/min |

0 |

|

|

Specifications of mainframe |

Host size |

m |

4.6×1.5×2.5 |

|

Weight of mainframe |

kg |

7000 |

|

Take one out of six as an example: the bottle blowing machine can stabilize 9000 bottles / hour for bottles less than 0.6L, can blow bottles with a maximum capacity of 0.6L, the maximum diameter of the bottle is 70mm, the maximum height of the bottle is 240mm, the size of the host is length x width x height: 4.8x2x2.5m, the weight is about 6.5 tons, and the energy consumption of the host equipment is 30kW left and right.

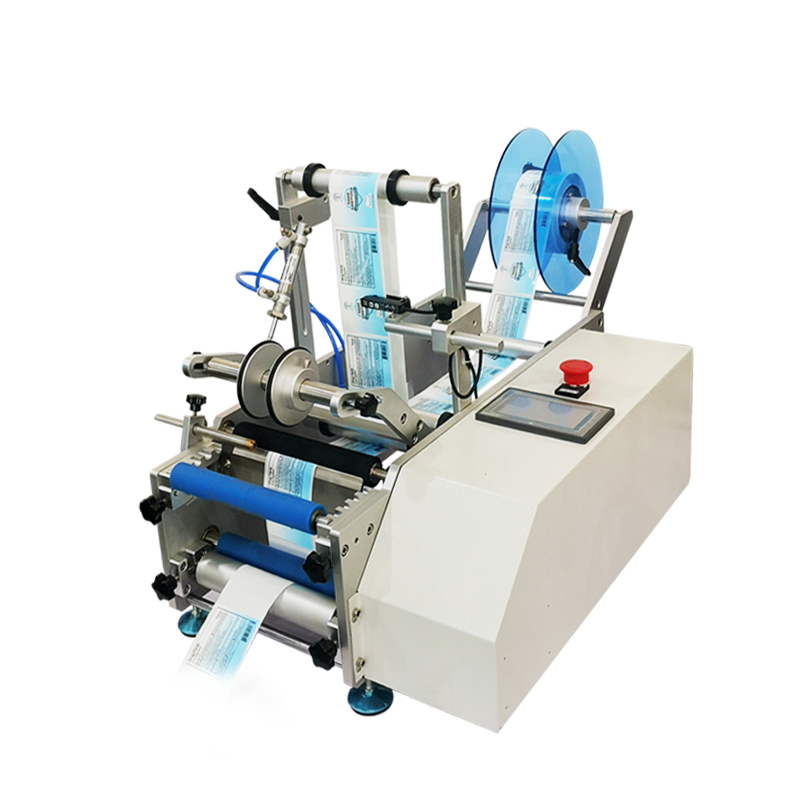

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for Good quality aluminium Filling line - Bottle Blowing Machine -zun shang , The product will supply to all over the world, such as: Sheffield , Indonesia , Juventus , If you have any requests, pls email Us with your detailed demands, we will give you the most wholesale Competitive Price with the Super Quality and the Unbeatable First-class Service ! We can give you the most competitive prices and high quality, because we are much more PROFESSIONAL! So please do not hesitate to contact us.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!