Products

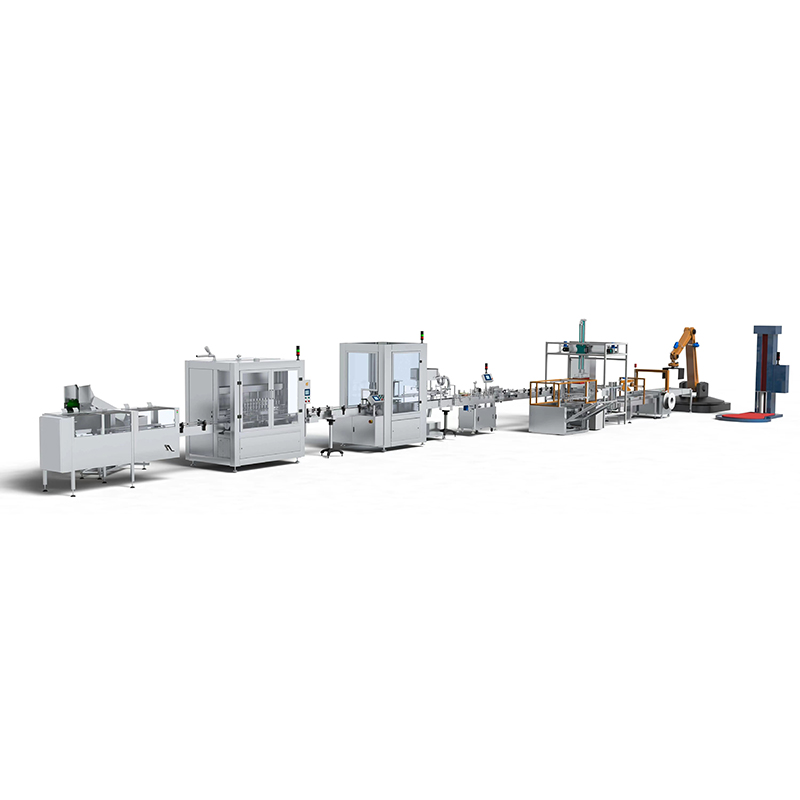

Fast delivery food additives Packaging production line - SH-2DGS-25L Barrel Liquid Weighing Filling Line -zun shang

Fast delivery food additives Packaging production line - SH-2DGS-25L Barrel Liquid Weighing Filling Line -zun shang Detail:

The weighing and filling line can be used for the accurate quantitative filling of various containers (iron drums or plastic drums and boxes) between 5 and 25kg. At the same time, the system can be used in humid, dangerous or other adverse environments.

The liquid weighing and filling line is an automatic quantitative measuring equipment. Its function is to automatically pack a large number of bulk liquid materials into predetermined containers. The liquid weighing and filling line has a high degree of automation, which can avoid material overflow as much as possible, prevent the pollution of the material itself to the environment as much as possible, and thus provide effective labor protection for operators. The liquid tank system is stable and reliable, easy to operate and accurate in weighing.

It is widely used in food processing, pharmaceutical and chemical industries. According to the needs of customers, it can be designed and manufactured into anti-corrosion liquid filling scales, food grade liquid filling scales and explosion-proof liquid filling scales.

Technical features

1. Automatic transportation, positioning and filling of packaging barrels / boxes

2. No filling without bucket, automatic peeling, automatic detection, start filling, fault detection, etc

3. The filling gun has no dripping and the height is convenient and adjustable

4. According to the situation, it can be made into explosion-proof type and anti-corrosion type

Technical parameters:

Number of filling heads: 2

Power supply voltage: AC220V 50 / 60Hz

Power: 500W

Air source: 0.5-0.7 MPa

Output: 60-120 barrels / hour (single measurement)

Filling capacity: 5-25kg

Filling accuracy: ± 0.05%

Overall dimension: 6000 × one thousand × 1200mm

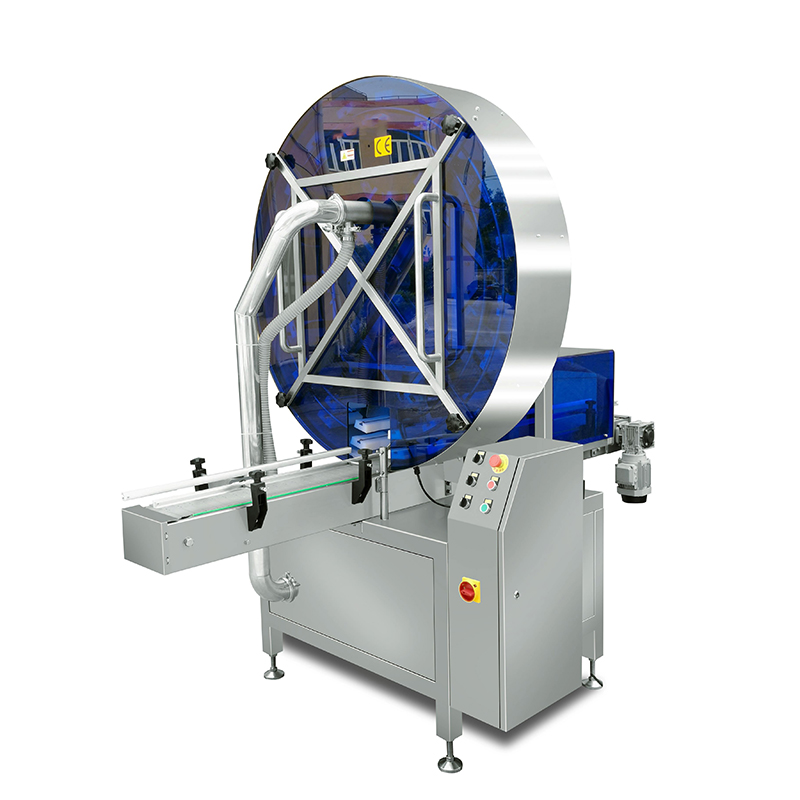

Product detail pictures:

Related Product Guide:

Gaining customer satisfaction is our company's aim forever. We will make great efforts to develop new and top-quality products, meet your special requirements and provide you with pre-sale, on-sale and after-sale services for Fast delivery food additives Packaging production line - SH-2DGS-25L Barrel Liquid Weighing Filling Line -zun shang , The product will supply to all over the world, such as: Macedonia , British , San Diego , Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant skilled knowledge, to develop advanced production equipment and production process , to create the first-call quality solutions, reasonable price , high quality of service , quick delivery , to offer you create new value .

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.