Products

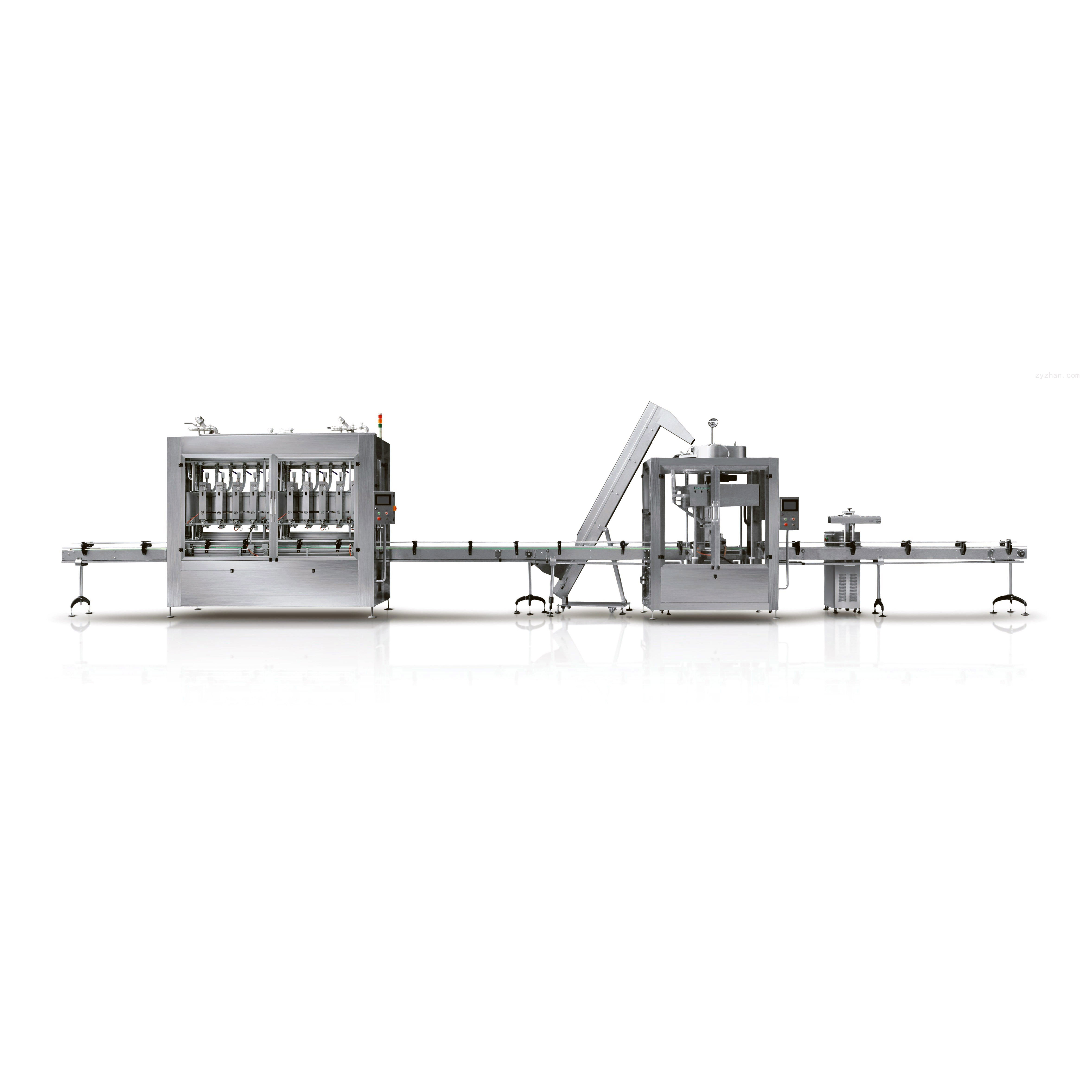

Factory supplied food Packaging equipment - SH-2DGS-25L Barrel Liquid Weighing Filling Line -zun shang

Factory supplied food Packaging equipment - SH-2DGS-25L Barrel Liquid Weighing Filling Line -zun shang Detail:

The weighing and filling line can be used for the accurate quantitative filling of various containers (iron drums or plastic drums and boxes) between 5 and 25kg. At the same time, the system can be used in humid, dangerous or other adverse environments.

The liquid weighing and filling line is an automatic quantitative measuring equipment. Its function is to automatically pack a large number of bulk liquid materials into predetermined containers. The liquid weighing and filling line has a high degree of automation, which can avoid material overflow as much as possible, prevent the pollution of the material itself to the environment as much as possible, and thus provide effective labor protection for operators. The liquid tank system is stable and reliable, easy to operate and accurate in weighing.

It is widely used in food processing, pharmaceutical and chemical industries. According to the needs of customers, it can be designed and manufactured into anti-corrosion liquid filling scales, food grade liquid filling scales and explosion-proof liquid filling scales.

Technical features

1. Automatic transportation, positioning and filling of packaging barrels / boxes

2. No filling without bucket, automatic peeling, automatic detection, start filling, fault detection, etc

3. The filling gun has no dripping and the height is convenient and adjustable

4. According to the situation, it can be made into explosion-proof type and anti-corrosion type

Technical parameters:

Number of filling heads: 2

Power supply voltage: AC220V 50 / 60Hz

Power: 500W

Air source: 0.5-0.7 MPa

Output: 60-120 barrels / hour (single measurement)

Filling capacity: 5-25kg

Filling accuracy: ± 0.05%

Overall dimension: 6000 × one thousand × 1200mm

Product detail pictures:

Related Product Guide:

As a way to provide you advantage and enlarge our organization, we even have inspectors in QC Crew and guarantee you our greatest assistance and product or service for Factory supplied food Packaging equipment - SH-2DGS-25L Barrel Liquid Weighing Filling Line -zun shang , The product will supply to all over the world, such as: India , Netherlands , Brasilia , Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!