Products

Factory Price Liquid Filling Machine - Double Sided Labeling Machine -zun shang

Factory Price Liquid Filling Machine - Double Sided Labeling Machine -zun shang Detail:

Basic use

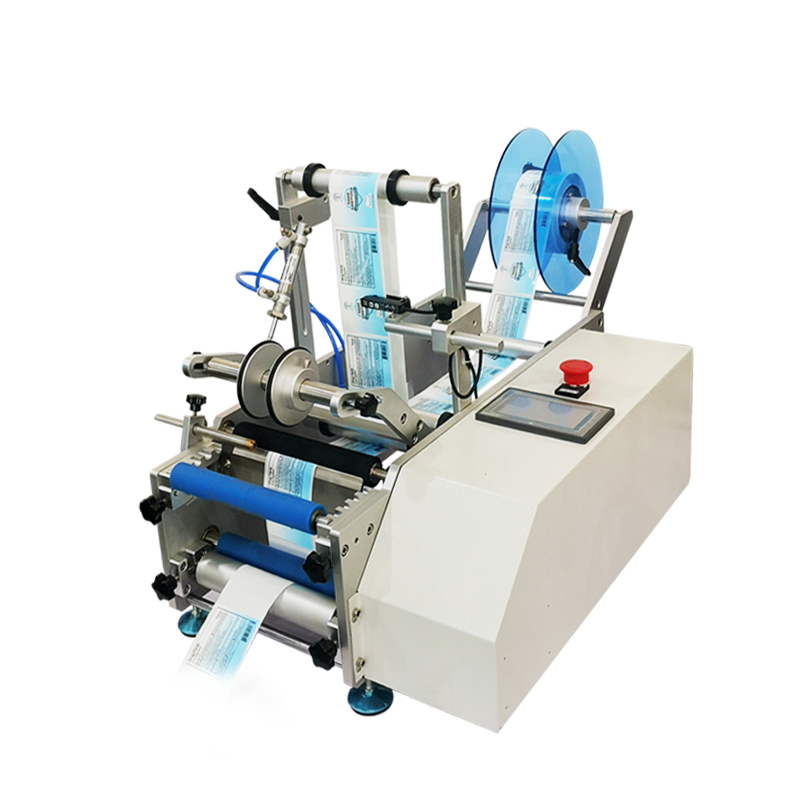

It is applicable to single-sided and double sided labeling of flat bottles, round bottles and square bottles, such as shampoo flat bottles, mineral water round bottles, square bottles, lubricating oil flat bottles, hand sanitizer round bottles, etc. single and double sided labeling, both sides of the same labeling, double labeling improves production efficiency, and is widely used in daily chemical, mineral water, cosmetics, petrochemical, pharmaceutical and other industries.

Scope of application

Applicable labels: self adhesive label, self adhesive film, electronic supervision code, bar code, etc.

Applicable products: products requiring labels on the side plane, large arc surface and circumferential surface.

Application Industry: widely used in cosmetics, daily chemicals, electronics, medicine, hardware, plastics and other industries.

Application examples: flat bottle labeling of shampoo, flat bottle labeling of lubricating oil, round bottle labeling of shampoo, etc.

Working process

* core working principle: the sensor detects the passing of the product and sends back the signal to the labeling control system. The control system controls the sending of the label at the appropriate position and attaches it to the position where the product is to be labeled. The product flows through the labeling device, and the label is coated and attached to the product. The labeling action of one label is completed.

* operation process: release products (can be connected to the assembly line) – > Product Transportation – > Product Separation – > labeling (automatically realized by the equipment) – > collect labeled products

Technical parameters: (the following are the technical parameters of the standard model. Other special requirements and functions can be customized).

◆ applicable label length (mm): 20mm ~ 200mm

◆ applicable label width (bottom paper width / mm): 20mm ~ 160mm

◆ applicable product size (long × wide × Height / thickness): length (conveying direction): 20mm ~ 250mm

Width (conveying width direction): 30mm ~ 90mm

Height: 60mm ~ 280mm

◆ applicable standard coil outer diameter (mm): φ 280mm

◆ applicable inner diameter of standard roll (mm): φ 76mm

◆ labeling accuracy (mm): ± 1.0mm

◆ standard output speed (M / min): step: 5 ~ 19m / min

Servo: 5 ~ 40m / min

◆ labeling speed (PCS / min): step: 30 ~ 160pcs / min

Servo: 40 ~ 180pcs / min

◆ conveying speed (M / min): 16m / min

◆ weight (kg): about 330kg

◆ frequency (Hz): 50Hz

◆ voltage (V): 220V

◆ power (W): 1100W (traction stepping)

1600W (traction servo)

◆ overall dimension of equipment (mm), (length) × wide × Height): 3000mm × 1450mm × 1600mm

Functional features

Powerful function, one machine can realize single-sided and double-sided labeling of four kinds of products (round bottle, flat bottle, square bottle and special-shaped bottle);

The double-sided rigid plastic synchronous guide chain is adopted to automatically ensure the neutrality of the bottles. It has low requirements for workers to put bottles and the docking of the assembly line. It greatly reduces the difficulty of workers’ operation or the docking of the assembly line. It can be produced in a single machine or connected to the assembly line;

Equipped with spring pressing top pressing mechanism to ensure stable product delivery and effectively eliminate the error of bottle height;

The automatic bottle separation mechanism is configured to automatically separate the spacing before bottle guide to ensure the stability of subsequent bottle guide, transportation and labeling;

The double labeling mechanism is configured to ensure the labeling accuracy for the first time, and the double extrusion labeling can effectively eliminate air bubbles and ensure that the label head and tail are tightly attached;

Intelligent control, automatic photoelectric tracking, with no label, no label automatic correction and label automatic detection functions, to avoid wasting labels and missing labels;

The main materials of the equipment are stainless steel and high-grade aluminum alloy, which comply with GMP production specifications. The overall structure is firm and beautiful.

Product detail pictures:

Related Product Guide:

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for Factory Price Liquid Filling Machine - Double Sided Labeling Machine -zun shang , The product will supply to all over the world, such as: Ethiopia , French , Bangladesh , Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products, please feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.