Products

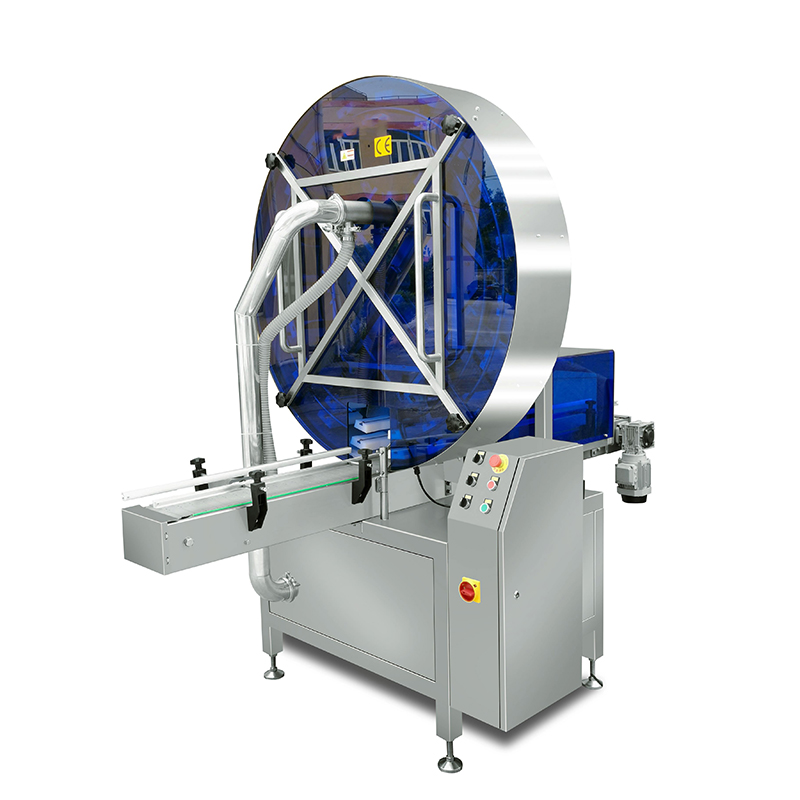

Factory Free sample Linear Filling Machine - Semi Automatic Labeling Machine -zun shang

Factory Free sample Linear Filling Machine - Semi Automatic Labeling Machine -zun shang Detail:

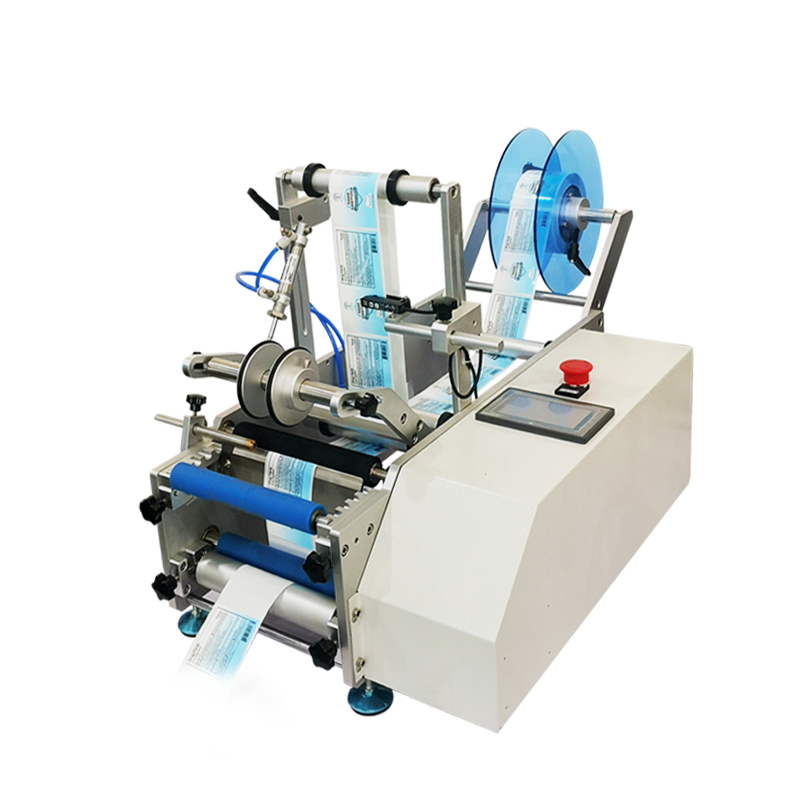

1. Basic purpose

It is suitable for labeling cylindrical objects of various specifications and small cone round bottles, such as xylitol, cosmetic round bottles, wine bottles, etc. It can realize full / half circle labeling and circumferential front and back labeling, and the spacing between front and back labels can be adjusted arbitrarily. It is widely used in food, cosmetics, chemical industry, medicine and other industries.

The self-contained touch screen can directly modify the parameters of the spacing between the front mark and the back mark on the screen, and it is convenient to adjust the spacing.

Optional circumferential positioning detection device to realize circumferential positioning and labeling.

Optional color matching tape coding machine and ink-jet printer, printing production batch number and other information at the same time, reducing packaging process and improving production efficiency.

2. Scope of application

Applicable labels: self adhesive label, self adhesive film, electronic supervision code, bar code, etc.

Applicable products: products requiring labels on the circumferential surface and conical surface; Single label or double label can be attached.

Application Industry: widely used in food, medicine, daily chemicals, electronics, hardware, plastics and other industries.

Application examples: labeling of oral liquid round bottle, labeling of Xilin bottle, labeling of xylitol, labeling of shampoo bottle, double labeling of wine, fixed-point labeling of wine, etc.

3. Working process

Core working principle: single label, double label switching function principle, circular positioning labeling principle, welcome to consult the manufacturer.

Operation process: place the product – > labeling (automatically realized by the equipment) – > take out the labeled product.

Technical parameters: the following are the technical parameters of the standard model. Other special requirements and functions can be customized

◆ applicable label length (mm): 15mm ~ 380mm

◆ applicable label width (bottom paper width / mm): 10mm ~ 160mm

◆ applicable product diameter (for round bottles): φ 15mm~ φ 120 mm

◆ applicable standard coil outer diameter (mm): φ 240mm

◆ applicable inner diameter of standard roll (mm): φ 76mm

◆ labeling accuracy (mm): ± 0.5mm

◆ standard output speed (M / min): 8m / min

◆ labeling speed (PCS / min): 15 ~ 35pcs / min (related to label length and manual operation speed)

◆ weight (kg): About 35kg

◆ frequency (Hz): 50Hz

◆ voltage (V): 220V

◆ power (W): 200W

◆ overall dimension of equipment (mm) (length × wide × Height): 920mm × 420mm × 500mm

Functional features

Powerful function, single label and double label labeling function can be switched at will, the distance between the front and back double labels can be flexibly adjusted, and the circumferential positioning function can be selected to set the position on the circumferential surface;

Support conical bottle labeling, with taper adjustment knob, simple adjustment can meet the labeling of conical bottle;

Good labeling quality, with double positioning of product positioning and label deviation correction, high docking coincidence of label head and tail, no wrinkle and no bubble, to improve and ensure quality;

Simple adjustment, one button switching of various functions, simple and fast labeling switching of different product labels, improving efficiency;

It is safe and hygienic and complies with GMP production requirements. The main materials are stainless steel and high-grade aluminum alloy, which are solid and durable;

Stable performance, controlled by PLC + optical fiber sensor electric control system, supporting long-time operation of equipment;

Convenient production management, with labeling counting, power saving mode, photoelectric tracking label and other functions, production management is easier;

Optional functions and components:

① Hot coding function;

② Circumferential positioning function;

③ Other functions (customized according to customer requirements).

Product detail pictures:

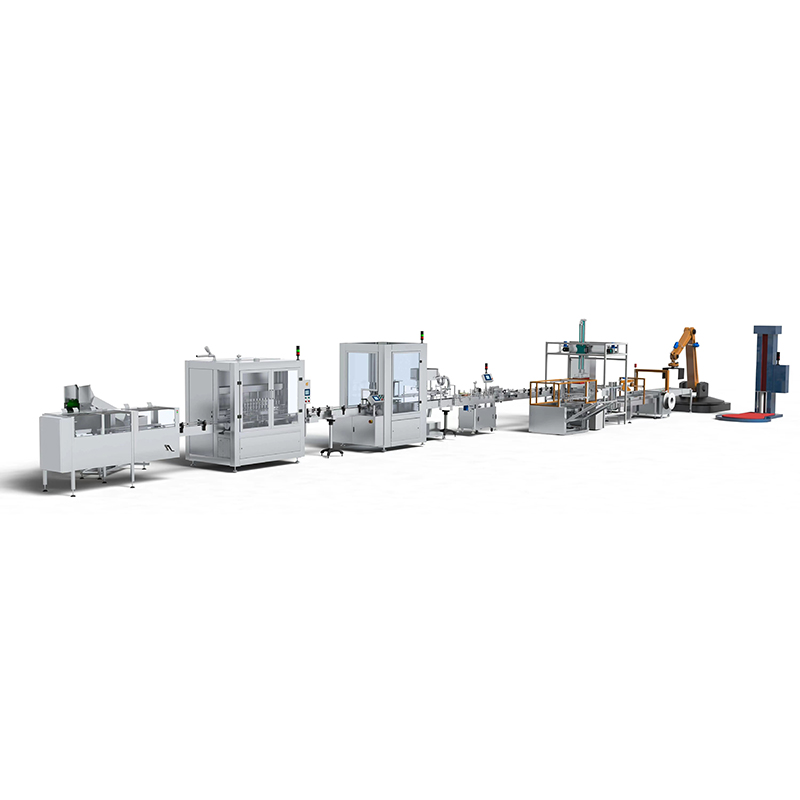

Related Product Guide:

Adhering to your principle of "quality, assistance, performance and growth", we have now gained trusts and praises from domestic and international customer for Factory Free sample Linear Filling Machine - Semi Automatic Labeling Machine -zun shang , The product will supply to all over the world, such as: Ireland , Poland , Kenya , Our company is an international supplier on this kind of merchandise. We offer an amazing selection of high-quality products. Our goal is to delight you with our distinctive collection of mindful products while providing value and excellent service. Our mission is simple: To provide the best products and service to our customers at the lowest prices possible.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.