Products

Beverage Filling Lines

Provide non-standard design for filling and packaging production line projects in industries such as cleaning, daily chemical, food and beverage, pharmaceutical and healthcare, pesticides and fertilizers, and provide one-stop services from scheme design to customer production. Main products: fully automatic bottle sorting machine, fully automatic labeling machine, fully automatic labeling machine, fully automatic packaging machine, various liquid and particle fully automatic filling production lines, etc.

1. 5000 bottles per hour — 36000 bottles of hot filled and medium temperature filled beverages

2. 3000 bottles per hour — 36000 bottles of mineral water and purified water production line

3. 5000 bottles per hour — 24000 bottles of aerated beverage production line (PET bottles, glass bottles)

4. 2000 bottles per hour – 24000 glass bottles of yellow rice wine and Baijiu production line

5. 5000 bottles per hour — 24000 bottles of pulp beverage mixed filling machine

6. Bottle sorting machine, labeling machine, film wrapping machine and other related supporting equipment

How much does a beverage production line cost? The investment and equipment analysis of a juice production line need to be designed according to the specifications and output of the equipment. Generally, the investment budget for a small juice beverage production line with a blending type is about 72, 000 US dollars. This type of equipment is more suitable for investment and is suitable for people who are starting a factory. The budget for a medium-sized beverage production line is about 80-1 million US dollars, and the budget for a large juice beverage is also over 2 million US dollars, The higher the output, the higher the price. The above is a blended fruit juice. Another type of fruit juice beverage is the freshly squeezed fruit juice beverage equipment. Due to the composition of multiple equipment, the investment for small fruit juice beverages will be higher than that of ordinary fruit juice beverage production lines, which is about 150 million yuan. This is for freshly squeezed fruit juice beverages, with a medium-sized fruit juice beverage of about 300000 yuan or more, and a large fruit juice beverage of over 400000 yuan or more.

Fully automatic bottle juice beverage production line, fresh squeezed beverage filling machine, small bottle juice beverage production equipment

https://youtu.be/5aDSneN–zQ?si=vXm4XmqtLGTVvZxz

Click to play video

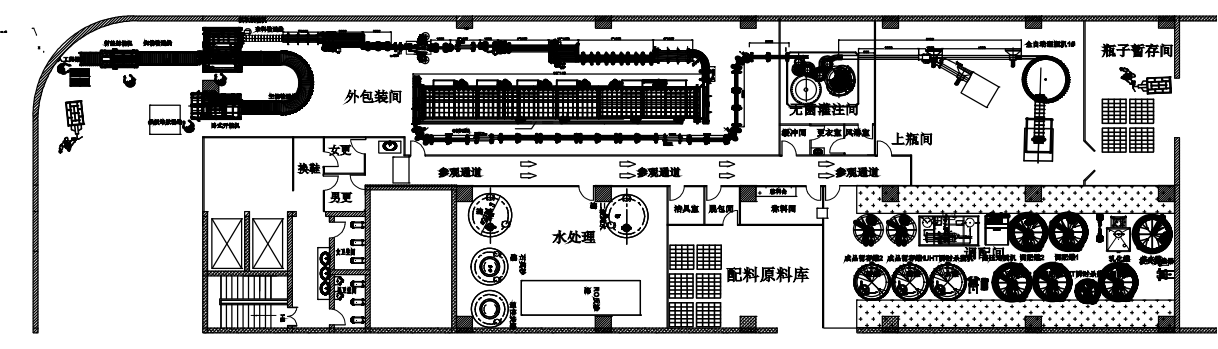

Juice drinks are composed of multiple sets of equipment. Generally, in order to establish a juice beverage factory, the location and area of the factory need to be determined first. The factory is generally designed according to the size of the production line, and the basic water content of juice drinks is more than 80%. Currently, juice drinks are divided into blended juice drinks and original fruit juice drinks based on their types. The recipe for blended drinks is relatively simple, and Siwei generally purchases juice powder from outside, The freshly formed raw materials are directly made into fruit juice using blending equipment. The production process of this type of fruit juice beverage is relatively simple, without the need for processing equipment such as raw fruits. It directly uses sterile water, fruit juice powder, and various seasoning agents. It can form a blended fruit juice beverage, which has a relatively low investment cost. Shiwei suggests that the blending system should include: sugar pot, syrup filter, blending tank, dual filter, high-pressure homogenizer, vacuum degasser, UHT ultra-high temperature instant sterilization.

The production of fresh fruit juice drinks can be divided into two types based on the characteristics of the original fruit and the type of fruit juice drinks: green juice drinks and cloudy juice drinks. Green juice drinks have relatively little juice content, and cavities squeeze out the liquid inside the fruit pulp through a similar squeezing method, and discharge the components of the fruit peel and residue. This type of content is relatively rare. There is also a method of beating the pulp. First, the original fruit is crushed into small particles, and then the content of the particles is squeezed out through screw equipment. Moreover, the particles that are sun dried on the net are relatively large, resulting in more pulp. Using beating the pulp can make more use of the juice, so the amount of original fruit used is relatively small, and more than 80% of the original fruit components can be utilized. The juice made from cloudy juice is relatively rich in ingredients.

The production of blended fruit juice beverages is the process of blending and blending beverages using water. After determining the source water, it is necessary to filter the water to ensure that it can be used for the blending of fruit juice beverages. The source water is generally taken from underground water wells or tap water, and filtering equipment is used to filter the water. Generally, filtered water according to pure water is used to mix fruit juice beverages, The taste of juice drinks made from purified water is better than that of mineral water, and the source water needs to be adjusted according to the actual water quality.

Mix the obtained juice into juice drinks. Some original fruit juices have a sour taste or a bitter taste. Therefore, food additives should be added to make them a fruit juice beverage with a rich taste, which can be accepted by the public and beneficial for launching into the market. In the process of juice blending, because the juice needs to be diluted and adjusted, sugar is added. In the blending process, an additional sugar melting pot is added to facilitate the addition of white sugar to dissolve and form the syrup used for blending. After blending, the mixture is homogenized through a homogenization system to make it finer, ensuring the same taste and making it more delicate. During the production process of fruit juice, there may be some air present, which can easily lead to the spoilage of the beverage. Vacuum dragging can remove oxygen from the fruit juice and extend its shelf life.

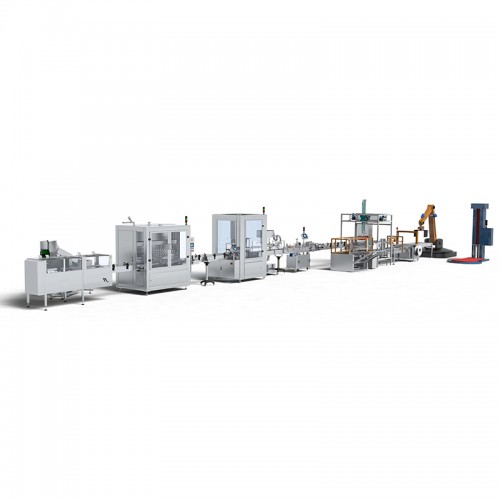

Processed beverages can be used for the task of filling production. The bottles used for hot filling are usually purchased from outside, and the cost of such bottles is relatively high, requiring high temperature resistance. Nowadays, many fruit juice drinks use high temperature filling, and plastic PET uses air ducts to transport bottles. Hook up bottles can be quickly transported on the air ducts. Directly reaching the filling equipment, the bottle is treated with sterile filtered water before use. The sterile water is evenly sprayed inside the bottle, and any foreign objects inside are cleaned and rinsed off. The high temperature filling machine of Schweiser Machinery adopts a process of flushing, filling, and sealing as a whole. High temperature resistant valves are used for filling, and a thick insulation layer is used inside the liquid cylinder. The juice beverage adopts a micro negative pressure filling structure, which has a fast filling speed and is suitable for products with a certain viscosity. The hydraulic cylinder is equipped with an automatic liquid replenishment system, which can automatically replenish liquid below the equipment’s liquid level.

How much does a beverage production line cost and how much does it cost to invest in a juice production line? Equipment analysis indicates that before products are launched into the market, it is often necessary to package the outer packaging of the bottles. For example, labeling can be done manually when the production volume is not high. When customers require a high degree of automation, a fully automatic labeling machine can also be configured for automatic labeling tasks. In the long run, It is more cost-effective to use fully automatic labeling. The automatic labeling machine is used together with a fully automatic steam shrinkage furnace, and the outer packaging produced is formed.